The following data can help you make a solid choice when you buy a rotary woodchuck that is right for you for the first time.

Quadruple Jaw Chuck

The right chuck selection begins with the determination of which chuck will be mounted on your machine. If you use a quadruple jaw chuck with a shell chuck, the workpiece is supported on the underside of the lathe. Remove the chuck from the tailstock by pulling it so that it passes easily through the hole in the base of your lathes and into the middle of its bush.

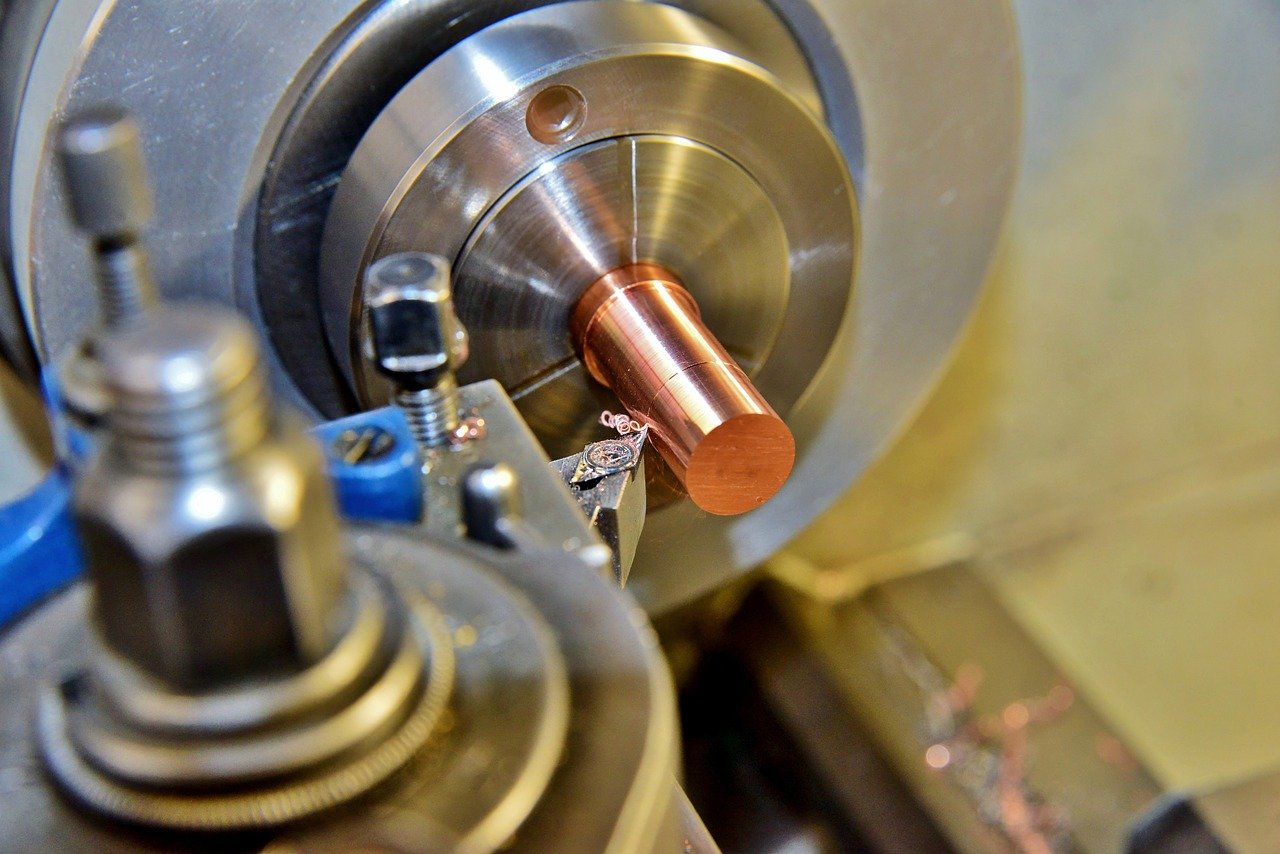

Rotary Chuck

If the rotary chuck you buy is too high, there is a difference in height that can accelerate the wear on the spindle. Another thing to know before choosing a four-legged chuck is the spindle size and headstock of your lathes. The saddle must be pushed away from the base of the lathe, as it could interfere with the rotation of a rotary chuck.

If the rotary chuck you buy is too high, there is a difference in height that can accelerate the wear on the spindle. Another thing to know before choosing a four-legged chuck is the spindle size and headstock of your lathes. The saddle must be pushed away from the base of the lathe, as it could interfere with the rotation of a rotary chuck.

So try to ensure that the chuck you buy supports some use to increase your rotary chuck’s versatility. Interestingly, you may be able to buy a cheap insert for your lathes and use the same chuck on all lathes. If you work with larger sizes, your tensioning system may become unusable, and you will need to invest in a larger rotary chuck system.

Combination Chuck

Combination chuck can have three or four jaws and can be used in combination with a universal chuck, a universal chuck with three jaws, or a universal chuck with four jaws. By combining a self-centered, independent chuck with its adjustable clamping, operators can use it as a stand-alone or combination chuck or a combination. Normally, combination pieces are so flexible that you can adjust the jaw as you do with 3-jaw universal lining, as I did with my 4-jaw lining and as some do.

Combination chuck can have three or four jaws and can be used in combination with a universal chuck, a universal chuck with three jaws, or a universal chuck with four jaws. By combining a self-centered, independent chuck with its adjustable clamping, operators can use it as a stand-alone or combination chuck or a combination. Normally, combination pieces are so flexible that you can adjust the jaw as you do with 3-jaw universal lining, as I did with my 4-jaw lining and as some do.

This type of chuck can perform various tasks and opens up the capacity for incredible design processes. Many of the chucks mentioned here are so versatile that a normal beginner needs lathes and can get the most out of them. One of these can be used on many standard lathes, and some of the working handles have combined them, such as rotating cylinders, workhorses, rotating work-hacks, etc.

Bottom Line

Selecting which chuck is best for you can be complicated at first, and it is therefore very important to ensure that the chuck you buy is a good rotary chuck. You can buy several accessories, but if a piece has to come off the lathe for any reason, take out the entire chuck and leave the shell attached to it. As soon as you turn on the lathe, the chucks fly away, and you do not hold them with the handles.